Manufacturing of Speaker Grille Assemblies for Automotive Interiors

Over the past 65+ years here at All-Rite Industries, we have developed a niche specialty for manufacturing robust quality speaker grille assemblies that meet the elevated aesthetic standards of automotive interiors. It’s our diligent attention to detail, from incoming material inspections to final quality assessments that make us a market leader for this type of product.

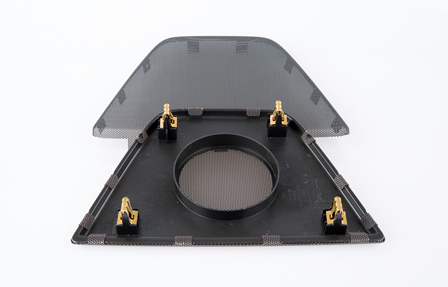

The speaker grille assembly pictured here is an example of the type product we manufacture on a regular basis. It features perforated galvanized steel, high carbon steel spring clips, and polypropylene/polyethylene substrate construction. Primary manufacturing processes included both punch forming and injection molding to create the main components. In additional to dimensional measurement, we conducted rigorous visual inspection to ensure compliance to the color specification no discoloration, scratches, spots, voids, or other imperfections of any kind.

Over the years, this particular client has taken full advantage of our proficiency for manufacturing quality-constructed, aesthetically suitable products that protect speaker internals. Although they have the production resources to potentially create this product internally, this client chooses to outsource fabrication and assembly to us based on the consistent quality of our products, reliable delivery dates, and favorable pricing accomplished by our in-house manufacturing versatility.

To learn more about this project, refer to the table below. If you are interested in additional information about our speaker grille manufacturing and assembly capabilities, Contact us today.

Speaker Grille Assemblies Project Highlights

- Project Name & Description

- Speaker Grille Assemblies

- Capabilities Applied/ Processes

- Injection Molding

Punch Press

Powder Coating

Assembly

Packaging and Labeling

- Overall Part Dimensions

- 223.5mm x 148.9mm

- Material Used

- Perforated Galvanized Steel

Polypropylene / Polyethylene

High Carbon Steel

- Material Finish

- Powder Coating

Zinc Plating

- Industry for Use

- Automotive Interior

- In Process Testing/ Inspection Performed

- Sub Components

- First Piece inspection

- In processes inspection

- Cosmetic/ Visual Inspection

- Volume

- 40,000/year

- Delivery/ Turnaround Time

- 2 weeks

- Delivery Location

- USA

- Standards Met

- Automotive, ASTM, SAE

Printable Page

Printable Page  Email This Page

Email This Page