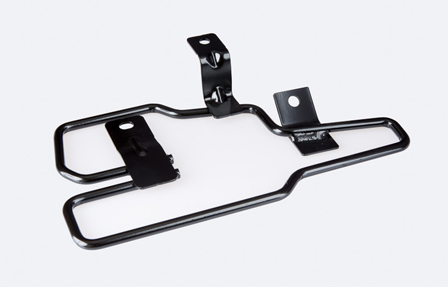

Precision Welding of Shield Brackets for Automotive Seats

Our strong background in the automotive interior parts industry, combined with our substantial production resources and diverse skills mix, enables All-Rite Industries to react quickly to support the time-constrained lead times that are not uncommon in this very competitive marketplace. For one of our clients, we provided quick-turn service for the production of the automotive seat bracket shown here. Within a very narrow timeline, we managed all aspects of Advanced Product Quality Planning, and accelerated PPAP timing.

Using low carbon steel, production of the individual components of this shield bracket involved CNC wire forming, four-slide stamping, as well as progressive punch press forming. Our tooling engineers designed and built a specialized Poka-yoke fixture for our precision computer-guided robotic MIG welding cells to ensure weld accuracy on what would ultimately be hundreds of thousands of parts. Due to its ability to evenly coat complex assemblies, we used an e-coat process to achieve the final finish requirements.

The vital function of this part demanded extreme quality assurance measures — each part was checked three times. Assessments involved wire gage inspections, bracket gaging, weld validation, and inspection of the final workpiece. A final assembly fixture is used to validate the true position of the significant characteristics to protect our customer.

Our wide range of in-house capabilities allowed us to provide complete, end-to-end production of this critical part within the agreed upon timeline and keep our client’s production launch in the U.S.A. and Mexico on time. To learn more about this project, refer to the table below. If you are interested in more information about any of our production services, contact us directly.

Welded Side Shield Bracket for Automotive Seat Project Highlights

- Project Name & Description

- Welded Side Shield Bracket for Automotive Seat

- Capabilities Applied/ Processes

- CNC Wire Forming

Punch Press

Four Slide

Robotic MIG Welding

Plating

Packaging and Labeling

- Material Used

- Low Carbon Steel

- Material Finish

- E-Coat

- Industry for Use

- Automotive Industry

- In Process Testing/ Inspection Performed

- Inspection for the Brackets

Wire Gauge inspection

Fixture for Welding (poka-yoke)

Final Inspection Attribute Gauging

- Volume

- 400,000+

- Delivery Location

- USA

Mexico

- Standards Met

- Automotive

SAE

Printable Page

Printable Page  Email This Page

Email This Page